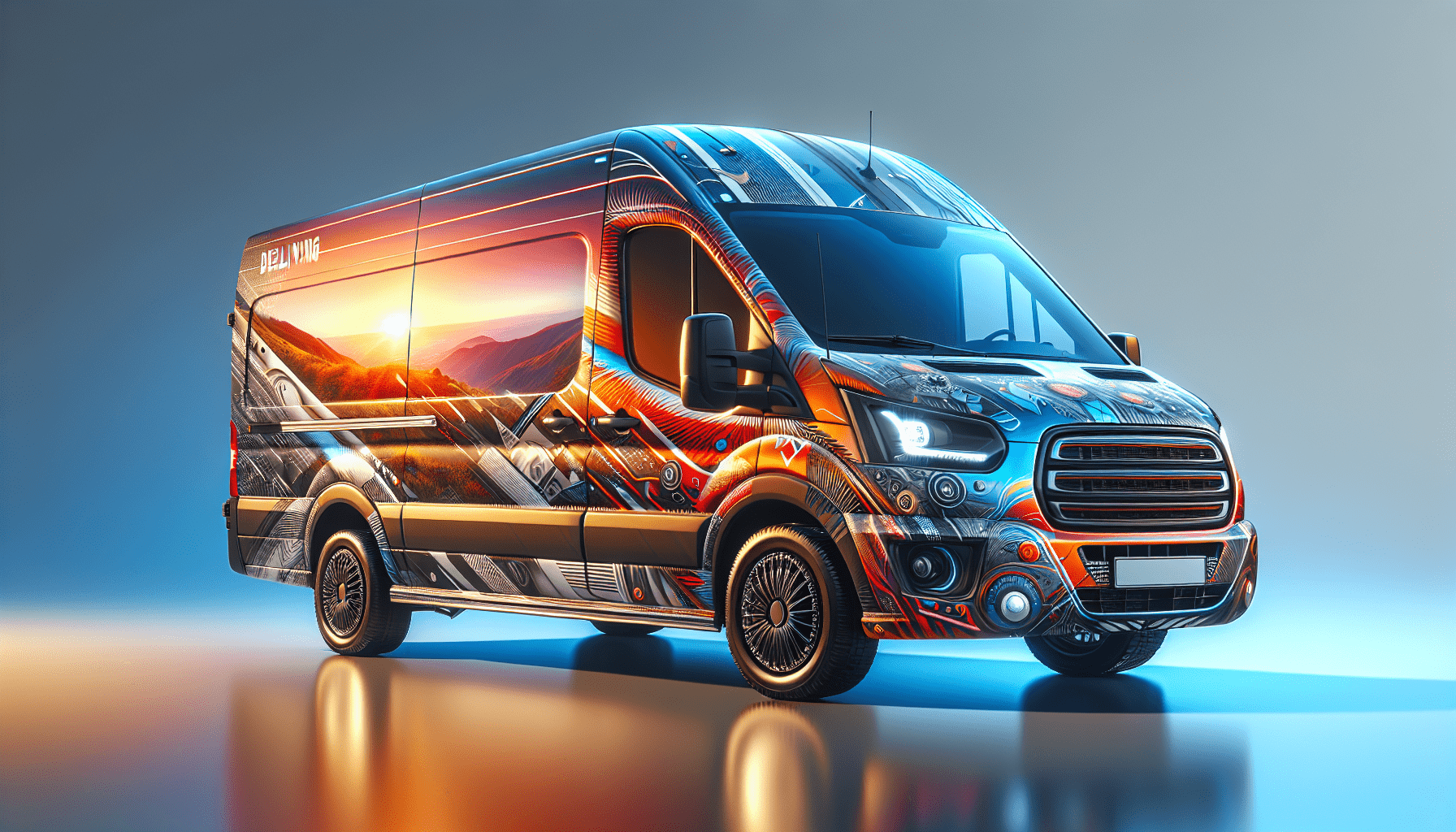

Have you ever wondered what makes a commercial vehicle wrap stand out? Is it the vibrant colors, the eye-catching design, or perhaps the innovative materials that bring it all together? Well, you’re not alone.

The world of commercial vehicle wraps is more fascinating than you might think. It’s a blend of art and science—creativity fused with technology to turn any commercial vehicle into a moving billboard.

Innovative Materials For Commercial Vehicle Wraps

What Are Commercial Vehicle Wraps?

Imagine driving down the street and seeing a truck covered in graphics promoting a new coffee shop or a mobile ice cream van with pictures of delectable treats. Those aren’t just painted designs; they are commercial vehicle wraps. Vehicle wraps are large vinyl decals or graphics applied over a vehicle’s paint to create a new look or promotion. They can cover the entire car or just part of it.

Why Use Vehicle Wraps?

You may wonder why businesses use wraps instead of painting their logos directly onto their fleet. The simple answer is versatility. Wraps can be custom-designed, easily removed, and even replaced without damaging the vehicle’s original paintwork. Think of it as a temporary tattoo that can be changed as often as you like. Plus, wraps protect the vehicle’s paint, adding another layer of value.

The Evolution of Vehicle Wrap Materials

Understanding the materials used for vehicle wraps is a bit like delving into the realms of fashion fabrics. Over time, these materials have evolved, improving the longevity, performance, and even the visual appeal of the wraps.

The Early Days

In the early days, vehicle wraps were made from basic vinyl materials. They were hardier but limited in flexibility and color options. These weren’t the easiest to apply and could be a nightmare to remove.

Modern-Day Innovations

Now, innovative materials have paved the way for more sophisticated wraps. The evolution has led to materials that are more durable, easier to apply, and offer a myriad of design possibilities. Some of the materials you’ll commonly find today include cast vinyl, calendared vinyl, and polymeric film. Each offers its own set of advantages and disadvantages.

| Material | Benefits | Limitations |

|---|---|---|

| Cast Vinyl | Extremely durable, ideal for complex curves, long-lasting color | Expensive, application demands high-skill |

| Calendared Vinyl | Cost-effective, great for flat surfaces, easy to remove | Less durable, prone to shrinking |

| Polymeric Film | Good balance of cost and durability, flexible | Limited color options, mid-tier lifespan |

Innovative Materials Making a Splash

Cast Vinyl Films

One of the most revolutionary materials in the vehicle wrap industry is cast vinyl. Known for their high durability and flexibility, cast vinyl films are excellent for vehicles with complex curves and shapes. They are created through a casting process, ensuring that they are thin yet extremely resilient.

Calendar Vinyl Films

Although not as flexible as cast vinyl, calendared vinyl films have their place in the vehicle wrap arena. They are thicker and more cost-effective, making them a popular choice for short-term or budget projects. The downside? They aren’t as durable and tend to shrink over time.

Polymeric Films

If you’re looking for a material that strikes a balance between cost and durability, polymeric films might just be your best bet. These films are designed to offer better performance than basic calendared vinyl while being more budget-friendly than cast vinyl. They fill a niche in which cost, durability, and aesthetics must all meet.

Specialized Materials

Reflective Vinyl Wraps

Ever noticed how some vehicles seem to glow in the dark? That’s reflective vinyl at work. Reflective wraps do more than just shine; they enhance visibility, making them perfect for emergency vehicles or businesses that operate at night. These materials contain glass bead elements that reflect light, making your vehicle dazzle in low-light conditions.

Carbon Fiber Wraps

Looking for a modern, sleek, and slightly futuristic aesthetic for your fleet? Carbon fiber wraps can give your vehicles just that. Apart from their chic look, these materials are robust and scratch-resistant. They are often used for high-end vehicles or businesses looking to make a statement.

Chrome Vinyl Wraps

Chrome vinyl wraps scream luxury. They are as close to a mirror finish as you can get and are usually available in various hues. The reflective property makes them impossible to ignore, although they can be quite tricky to apply and maintain.

Textured Vinyl Wraps

What if you could add a tactile element to your vehicle’s wrap? Textured vinyl wraps give you this option. Think about faux leather, brushed metal, or even wood grain textures on the sides of a van. These unique textures make your vehicle not just a visual, but also a sensory experience for anyone who gets close enough.

Sustainability & Eco-Friendly Options

In a world increasingly aware of its environmental footprint, it’s crucial to consider sustainable materials. Several manufacturers are developing eco-friendly vinyl and inks that minimize waste and reduce harmful emissions. These wraps provide the same vivid colors and lasting durability as their non-eco counterparts but with a lighter environmental impact.

Biodegradable Vinyl

These materials break down more quickly than traditional vinyl when disposed of correctly. If your company is committed to sustainability, biodegradable vinyl is an excellent choice.

PVC-Free Vinyl

Polyvinyl chloride (PVC) is a common component of traditional vinyl. However, it’s not the most eco-friendly material. Several companies are now producing PVC-free options that deliver the same level of quality without environmental drawbacks.

The Science of Adhesives

Behind every great wrap is a great adhesive. The adhesive technology used in vehicle wraps has seen significant advancement, ensuring easier installation and longer-lasting results.

Pressure-Sensitive Adhesives

These adhesives activate under pressure, making the application straightforward. All you need is a decent amount of pressure to make them stick, allowing for easy adjustments during installation.

Air-Release Technology

One of the most frustrating aspects of DIY wraps is dealing with air bubbles. Enter air-release technology! This innovative adhesive design allows trapped air to escape, making the wrap appear smooth and bubble-free.

Hot Melt Adhesives

Some wraps use hot melt adhesives, which become sticky upon heating. These are perfect for complex installations requiring a high degree of precision and hold.

Application Techniques

While having innovative materials is essential, knowing how to apply them is equally crucial. A poorly applied wrap can make even the best materials look subpar.

Wet Application

The wet application involves using a solution (often water mixed with a bit of soap) to ease the placement of the vinyl wrap. This method allows minor adjustments before the adhesive sets, making it somewhat forgiving for beginners.

Dry Application

On the flip side, dry application leverages modern adhesive technologies, like pressure-sensitive adhesives and air-release technology, to simplify the process. This method requires a steady hand but offers immediate results without the drying time.

Heat Assisted Application

For materials like cast vinyl, a bit of heat can go a long way. Using a heat gun or a torch helps mold the wrap-around curves and crevices, ensuring a snug fit.

| Application Method | Pros | Cons |

|---|---|---|

| Wet Application | Allows for repositioning, reduces bubbles | Requires longer drying time, not suited for all vinyl |

| Dry Application | Faster application, modern adhesives reduce bubbles | Requires more skill, less forgiving |

| Heat Assisted | Excellent for complex shapes, strong bond | The risk of over-heating needs expertise |

Post-Application Care

Even the best materials need proper care to ensure longevity. Think of it as maintaining a new coat of paint on your vehicle.

Cleaning and Maintenance

It’s essential to clean your wrap regularly. Use mild soap and water, avoiding abrasive materials that could scratch the vinyl. Specialized cleaning solutions designed for vehicle wraps are also available.

Avoiding High-Pressure Washes

High-pressure washes can lift the edges of your wrap, leading to peeling. Stick to hand washes or gentle automated car washes that won’t damage the material.

Parking Considerations

Where you park your wrapped vehicle matters. Excessive exposure to sunlight can cause fading, while salty environments (like coastal areas) can accelerate wear. Opt for shaded parking or indoor storage when possible.

The Cost Factor

When considering wraps, the cost can be a significant factor. The type of material, the vehicle size, and the complexity of the design all play a role in the final price.

Material Costs

Generally, cast vinyl and specialized materials like chrome or carbon fiber are on the higher end of the cost spectrum. On the other hand, calendared vinyl and polymeric films offer budget-friendly options without compromising too much on quality.

Labor Costs

The skill level needed for applying wraps also influences labor costs. Specialists who can handle complex designs and make use of innovative materials will naturally charge more for their expertise.

Conclusion

Innovative materials for commercial vehicle wraps have revolutionized the way we advertise and personalize vehicles. Whether you opt for sturdy cast vinyl, budget-friendly calendared vinyl, or any of the specialized materials like reflective or textured wraps, each option offers unique advantages and challenges. Proper application and maintenance can significantly extend the life of your wrap, ensuring that your commercial vehicle remains a head-turner for years to come.

For those looking to take the plunge into the world of vehicle wraps, more questions or detailed information can be obtained directly from:

7655 E Redfield Rd #110

Scottsdale, AZ 85260

(480) 849-8478

Ready to turn your vehicle into a mobile masterpiece? You now know what it takes!